Overcoming Supply Chain Challenges: The Impact of CRM on Manufacturing and Wholesale Distribution

Over the past few years, supply chain management has become especially difficult to navigate. As such, manufacturing enterprises are now facing new challenges in managing and navigating dynamic markets. These bottlenecks can negatively impact the bottom line, from fluctuating demand and inventory mismanagement, to logistical inefficiencies and customer service issues.

However, by leveraging CRM applications, businesses can effectively address these challenges, enhancing operational efficiency and customer satisfaction. How can CRM solutions help manufacturers and wholesale distributors navigate complex markets and new challenges? We’ll cover the topic below.

What we'll Cover:

Supply Chain Challenges in Manufacturing and Wholesale Distribution

Before we focus on how CRM can help navigate modern challenges in the industry, we’ll first need to establish which are the most common challenges faced by manufacturers and wholesale distributors:

Demand Forecasting

Customer demand predictions have always been challenging to navigate. The inability to clearly establish demand will result in overstocking or stockouts, ultimately impacting ROI and customer experience.

Inventory Management

From stocking issues to product line diversity, inventory management can be complex due to a lack of proper technology and insights. Customer requirements are dynamic, and so should manufacturers’ inventory. Besides, proper inventory management can help manufacturers reduce costs in certain areas, such as storage.

Lack of Logistical Efficiency

Goods need to pass through intermediary entities to reach end users. This has always been a tremendous challenge in manufacturing since manufacturers and distributors need to figure out ways to reduce transportation times and cut costs. Effective supply chain management allows manufacturers to ensure that their products are delivered on time and the risk of product damage is minimal.

Extend Customer Lifecycle and Boost Customer Experience

The manufacturing space has become highly competitive. Ensuring good collaboration with customers and seamless interactions with them is essential for manufacturers who want to secure a better market position, boost brand recognition, and increase their upsell, cross-sell, and resell opportunities. However, due to a lack of proper customer care and customer experience levels, this is near impossible.

CRM & Manufacturing: Navigating Common Challenges With a Few Clicks

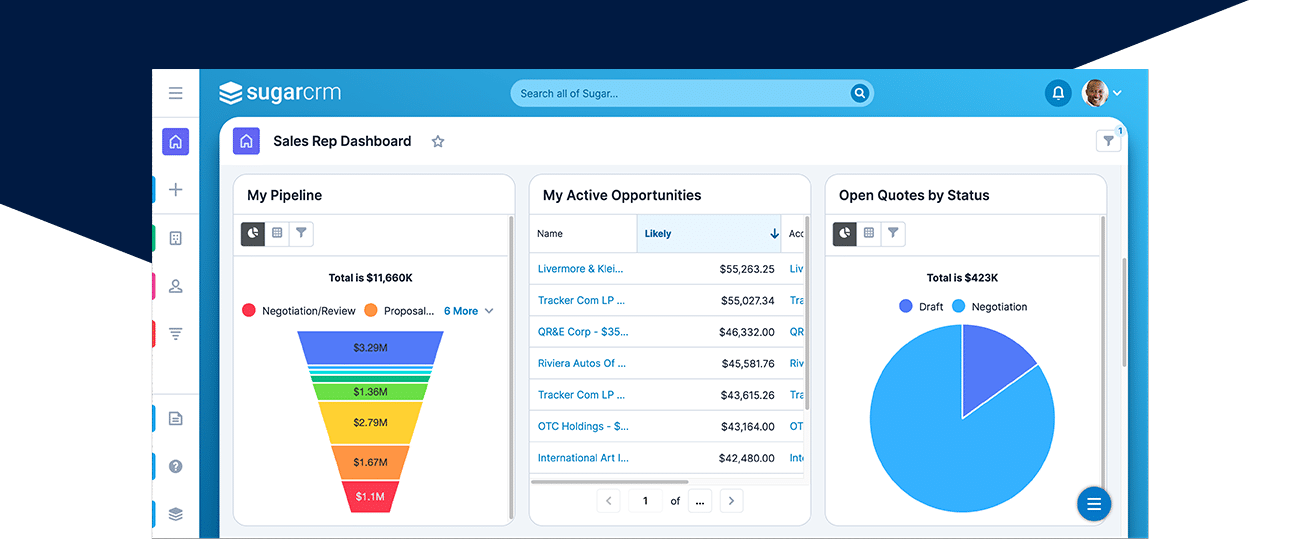

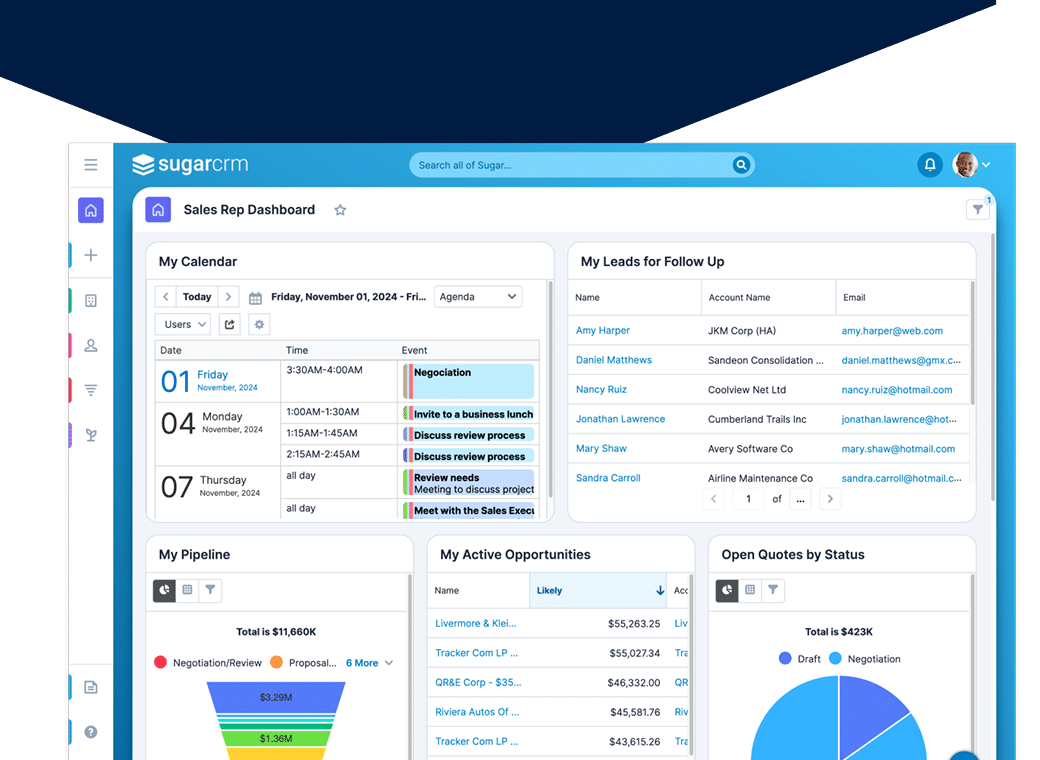

Today’s CRM solutions have become critical for companies, regardless of sector or industry. With extensive capabilities, these are far from glorified Rolodexes like in the past. Today, CRM solutions can be seamlessly integrated with ERP tools to ensure that all operations within manufacturing enterprises, from front-office to back-office, are synced and live in a central hub. Below are only some areas that can be significantly improved by adopting a robust CRM solution.

#1. Enhanced Demand Forecasting

Robust CRM solutions can analyze vast amounts of data. By integrating CRM tools with ERP solutions, manufacturers and wholesale distributors ensure access to even larger amounts of data that can be leveraged to generate accurate forecasting reports.

Ensure you select a CRM solution offering predictive AI capabilities for enhanced demand forecasting. These tools can compile data from multiple sources, both internal and external, and generate even accurate forecasts that account for market trends, global events that may impact demand, and supply chain bottlenecks.

Besides, by integrating ERP and CRM solutions, manufacturers have more advantages in terms of forecasting:

- Unified data source: Having two separate systems, one for back-office operations and one for customer-centric integrations, can negatively impact forecasting models and, thus, their accuracy.

- Real-time access to data: CRM & ERP integrations offer quick access to data from both systems without delays or downtime. A similar solution can help manufacturers gain more flexibility and adapt to changing scenarios.

- Predictive data analysis: While ERP tools generally host vast amounts of historical data, CRMs leverage customer-centric information. Predictive analytics will help you compile both information into valuable insights focusing on what interests you: trends, seasonality, and cyclical changes in customer behavior. All these variables are necessary for establishing future demand.

- Enhanced segmentation and personalization capabilities: By integrating CRM and ERP solutions, manufacturers have quick access to detailed information about customer segments. By knowing what types of products and volumes of products are consumed by each segment, manufacturers can better plan their production and operations while reducing waste.

- Improved resource allocation: With improved forecasting capabilities, manufacturers can optimize resource allocation, reduce raw material waste, and improve overall efficiency.

#2. Enhanced Inventory Management Capabilities

CRM applications can provide real-time insights into stock levels and customer orders when integrated with inventory management solutions. This way, manufacturers can adjust and adapt their production based on accurate data from both solutions: customer data, current stock data, customer order information, etc. A similar integration can trigger automatic reordering processes or alert managers when it identifies potential issues, such as the need to accelerate production for high-demand items or to run promotions and offers to move surplus stock.

#3. Improved Logistics

Supply chains are complex, and customer journeys are lengthy. As such, manufacturers and wholesale distributors must find ways to improve planning and logistics. Everything needs to be automated and synchronized to ensure proper logistics across the line, and operations need a solid foundation of data and analytics, from order management to product delivery. How can CRM solutions improve logistics?

- Improved visibility across the supply chain: Better visibility into both front-office and back-office operations allows logistics teams to track inventory and shipments in real-time. Such integrations offer valuable insights into when a batch was manufactured, when products are planned to be shipped, where these are in transit, and when they reach their destination. This information is crucial for coordinating with transportation providers and managing delivery schedules effectively.

- Dynamic response to market conditions: Markets are volatile and depend on various socioeconomic and political factors. With better forecasting tools derived from data consolidated between ERP and CRM solutions, manufacturers can quickly adapt their logistics strategies to changes in product demand. This dynamic response capability is crucial for managing peak seasons, promotions, or any unexpected surge in orders.

- Order accuracy and delivery performance: Integrations between CRM and ERP tools are a great way to ensure customer orders are processed efficiently and accurately. With complete access to customer history and inventory data, sales and customer service teams can provide accurate information to customers regarding product availability and delivery times.

#4. Boost Customer Satisfaction and Experience

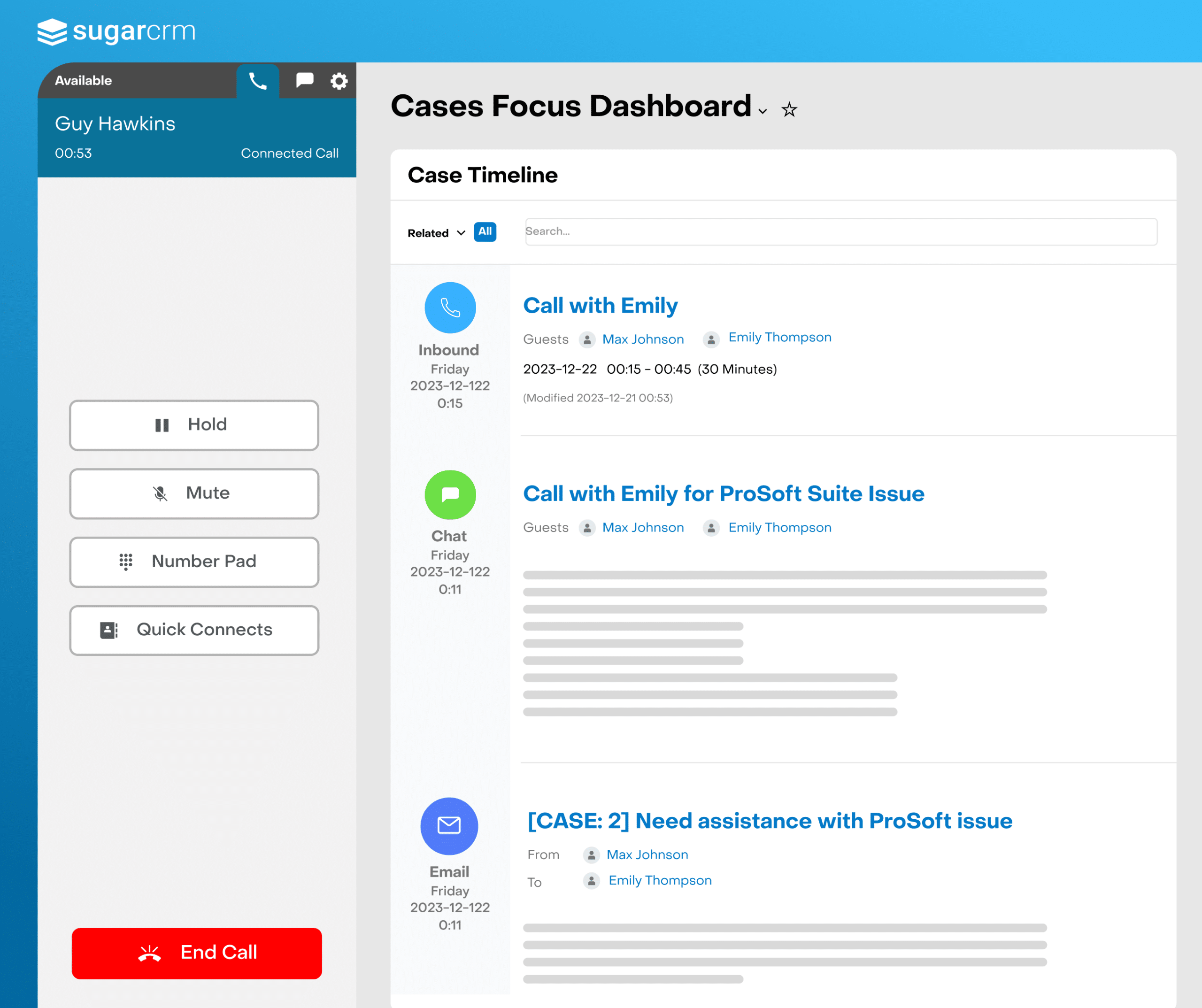

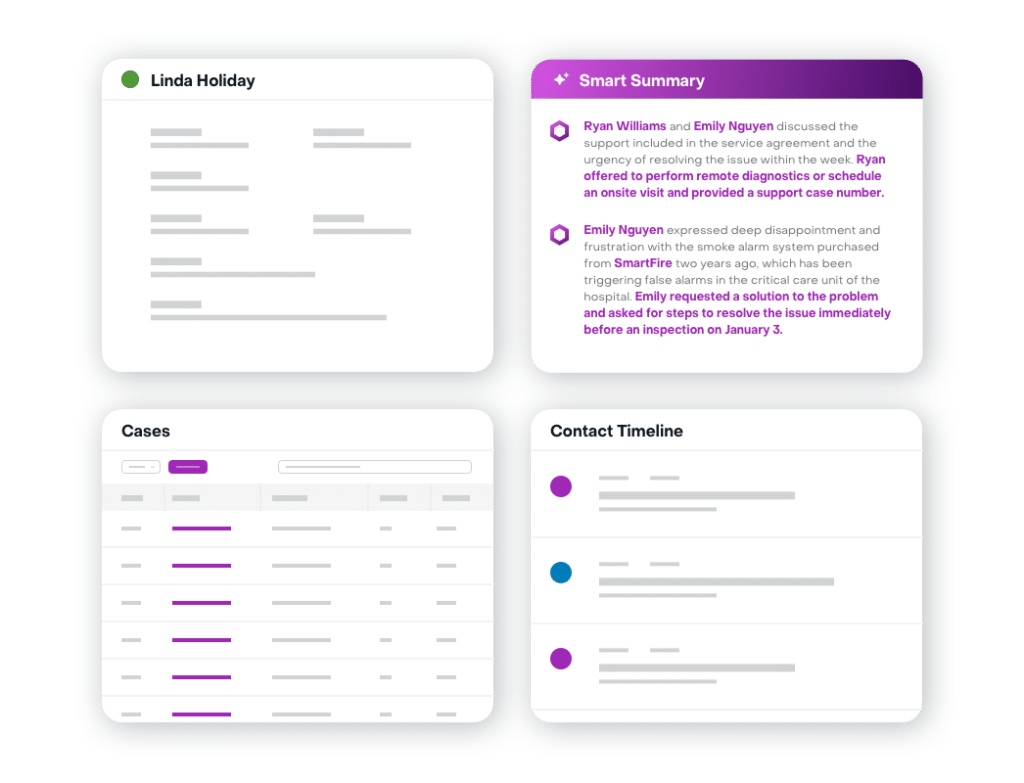

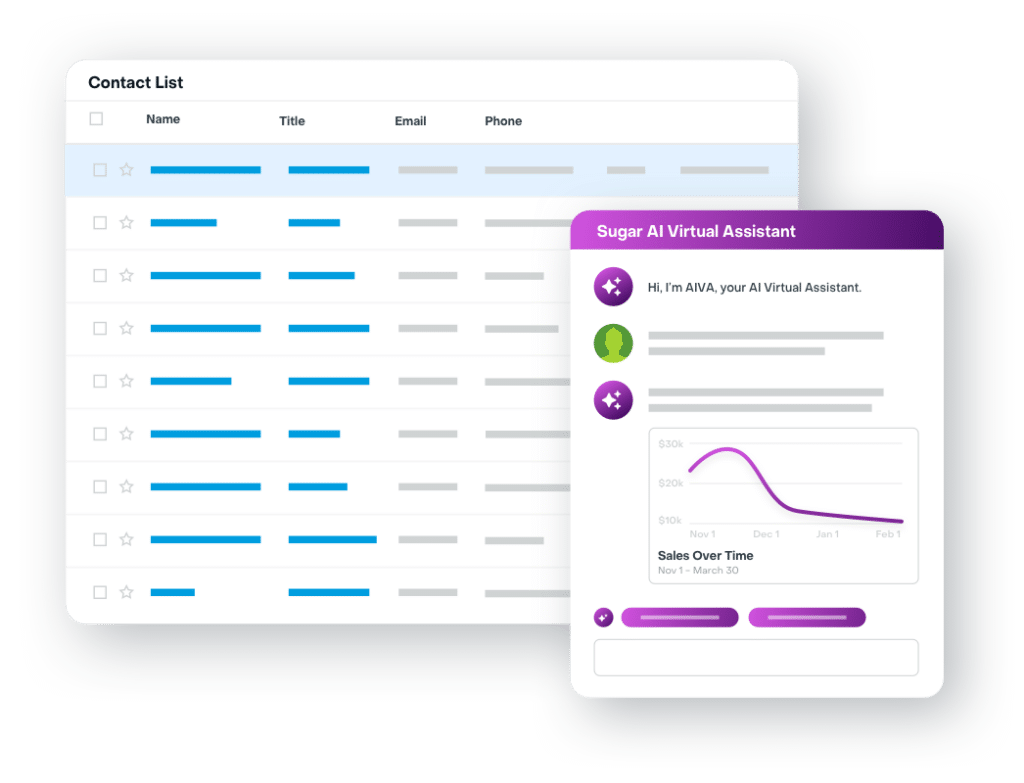

With CRM and ERP integrations, sales and customer support teams can access centralized customer data. This can help enhance customer interactions by making it easier for your teams to respond to customer inquiries, manage orders, and resolve issues promptly. Reduced response times boost customer satisfaction and loyalty. CRM tools can also help personalize marketing efforts and sales strategies based on customer preferences and purchase history, leading to more effective upselling and cross-selling opportunities. Recent-day CRMs also leverage generative AI capabilities, making each interaction easier to navigate:

- Compose personalized sales and marketing content

- Find answers and recommendations in no time

- Summarize customer data and information

- Create ad-hoc reports and workflows.

Interested in learning more about how CRM tools can accelerate the growth of your manufacturing company? Read our Connecting the Manufacturing Value Chain Guide!