Servitization: When Manufacturers Become Service Companies

It’s that time of year again when techies bring out the crystal ball and prophesize about what’s coming in the next year. Not to be left behind, I opened my browser this morning to an article about Apple that speaks directly to what I see as one of the most important paradigm shifts we will see in the manufacturing industry this decade…manufacturing companies reinventing themselves as services companies.

It’s that time of year again when techies bring out the crystal ball and prophesize about what’s coming in the next year. Not to be left behind, I opened my browser this morning to an article about Apple that speaks directly to what I see as one of the most important paradigm shifts we will see in the manufacturing industry this decade…manufacturing companies reinventing themselves as services companies.

To be fair, this article illustrates that Apple has been on the road to becoming a services company for a while. That’s not the new news here. What is new is Apple’s latest announcement of distributing Apple iTunes service on non-Apple devices. That’s a big step forward for a company that historically focused only on an “owned” ecosystem of devices. But the key point remains the same…Apple has a specific plan to educate the market that “we’re a service company now” and that they aren’t just a device manufacturer any longer.

There’s actually a word for this trend. It’s called “servitization”. While certainly slightly awkward to pronounce and likely untranslatable to most languages, it’s a key strategic driver for growth in the manufacturing industry. The idea is that a manufacturer offers more than just a widget, but rather also the services to effectively use, maintain and upgrade that widget. It basically means that the manufacturer supplies a full solution to the purchaser rather than just a widget that might, or might not, solve a problem. And fueling this new way for manufacturers to deliver killer products are exciting new technologies like IoT, Cloud and AI.

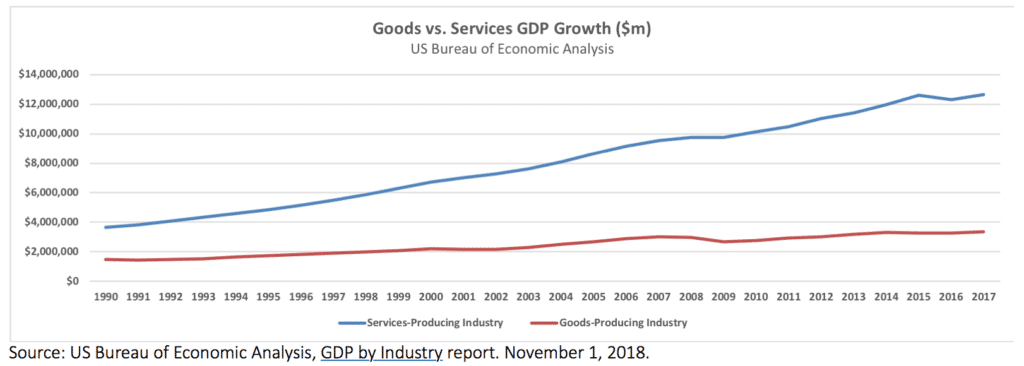

And if you look at the economic data behind these trends, you will see that investing in servitization is more than just a “nice to have” for the winners in manufacturing. Financial growth in the services industries has far surpassed than in the manufacturing industries for years. Simply put, people spend more money on services than they do on goods. Businesses and consumers don’t just want “things” any more. They want solutions that go beyond solving today’s problems, but also solve tomorrow’s problems. From the iPhone that streams cool content to the Nest thermostat that tells you how to save money on your heating bill to Porsche’s new Passport car service that gives you the latest hot ride, manufacturers know that the future is about delivering products and services integrated together.

But here’s a key part of the servitization equation that you may not have thought about yet. These new services complementing the use of manufactured goods come with new ways to interact with your customers. In fact, in the 2017 Barclay Annual Manufacturing Report, nearly three-fourths of the survey respondents saw a key goal of servitization as “satisfying customer requirements… that lead[s] to deeper customer relationships.”

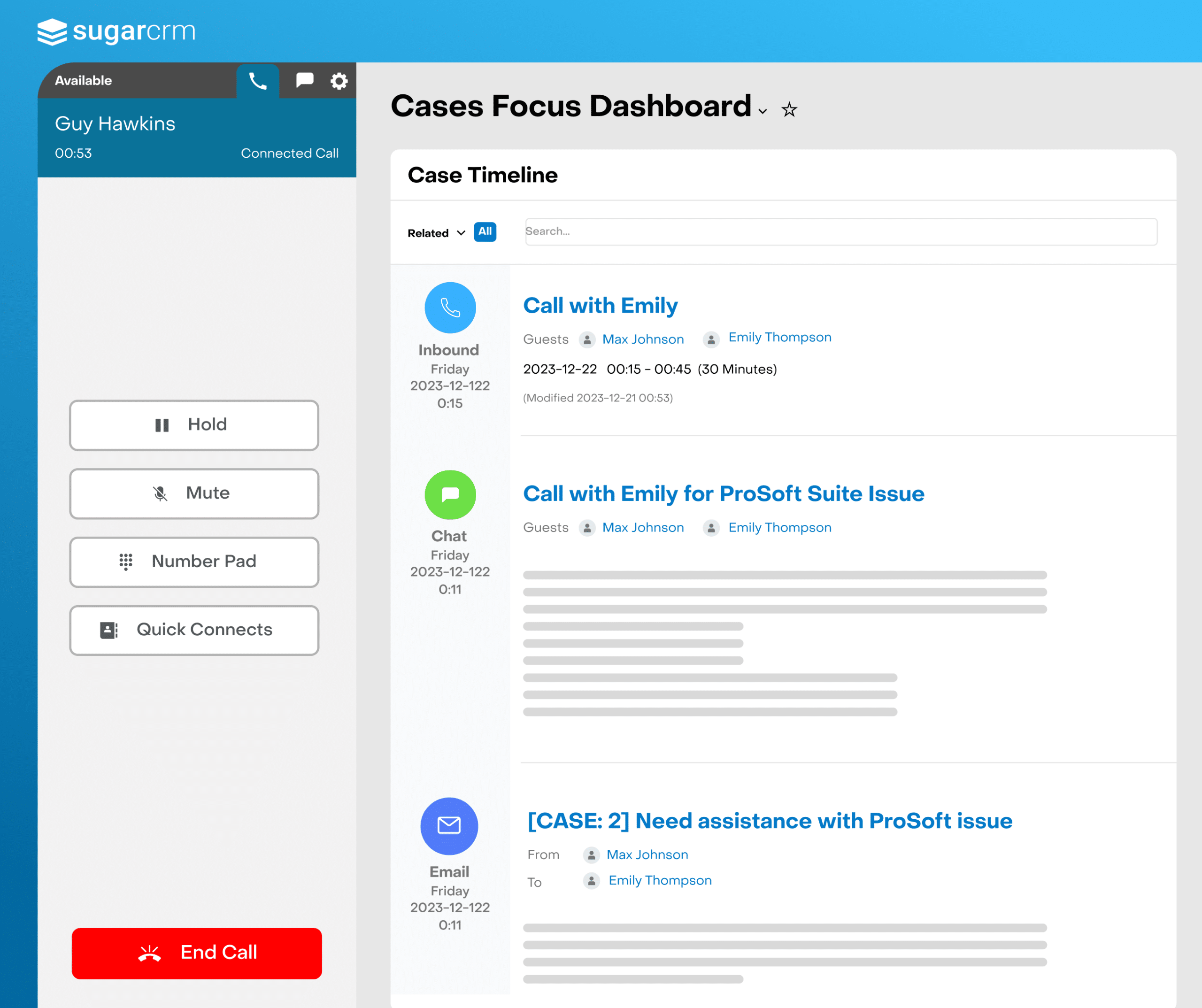

Also behind these new servitization business models comes the need to build a recurring revenue machine. In short, manufacturing companies that are building a servitization business model invariably need to figure out how also become a software-as-a-service business. This means at the very least expanding your customer service team to support the new SaaS offerings, but also building out a new customer success function to drive retention and even sometimes new sales and marketing functions to sign up the SaaS prospects.

For many established companies, this requires a retooling of existing processes and systems. For the current generation of new manufacturing companies, this is the DNA they are growing up with. In either case, it’s in your best interest to partner with a CRM provider that specializes in CRM for manufacturing companies. With customers like IBM, Agfa, and Greif, you should definitely learn more about how SugarCRM is the best CRM solution for the manufacturing industry.